As the world races to meet growing global energy demand while massive reducing greenhouse gas emissions, there has been resurging interest in nuclear power. Due to the potential for catastrophic failure inherent in the technology (and the infamous historical examples of such failures), attempts to expand nuclear capacity are often controversial and contested. However, nuclear is already well-established as one of the largest sources of emissions-free energy, generating nearly 1/5 of America’s electricity. Furthermore, it is highly efficient and requires much less land than other clean energy sources (360x less than wind and 75x less than solar for a typical 1,000-megawatt facility). With the rise of cost-savings and resource-conserving innovations such as small modular reactors (SMRs) and thorium reactors, along with signs that the US may start investing in nuclear recycling, we can expect to see a significant expansion of nuclear power over the coming decade.

Saving Space and Cost: Small Modular Reactors

While the traditional nuclear plants do require a lot less land per megawatt than wind or solar, they aren’t exactly low profile. Small modular reactors (SMRs) have a much more manageable footprint. Each SMR has capacity up to 300 MW(e) per unit (~1/3 of the generating capacity of a conventional reactor) and can be deployed individually or together in a large facility; this flexibility may enable nuclear power in areas where space constraints would otherwise make it infeasible.

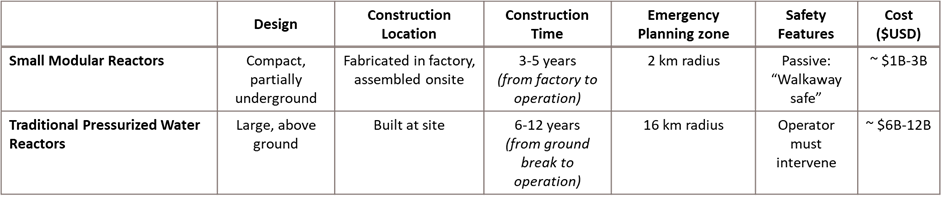

Furthermore, whereas conventional nuclear plants may take up to 12 years to build and bring online, SMRs can be prefabricated, which cuts down on delays, costs, and effects that may arise from building the reactor onsite. Thus, although the timeline for initial project planning, contracting, and licensing for an SMR vs. traditional reactor is similar, SMRs take less time on average to construct and start operating (just 3-5 years).

Alleviating Resource Constraints: Thorium Reactors

Conventional nuclear reactors use Uranium 235 (U-235) as feedstock, but there is another reaction pathway that relies instead on thorium. Thorium is a largely untapped source material that produces less harmful byproducts and has greater potential for harvesting and reuse. It is also heavily concentrated in countries that have less access to uranium; for instance, India has 1-2% of the global uranium reserve, but 12-33% of the global thorium reserve. Thorium reactor technology is not new — active thorium reactors were operating globally as recently as the 1980s — but it lost out decades ago to the more cost-effective uranium reactor technology. Now, as interest in expanding nuclear capacity surges, thorium reactors are receiving renewed attention.

The most notable thorium-fueled nuclear reactor projects in recent years are all located overseas. A trial facility came online in Wuwei, China in September 2021 and has produced 2 MW(e) to date. India is building heavy water and fast-breeder reactors to leverage its abundant natural stores of thorium, and El Salvador recently signed a memorandum of understanding with the Thorium Energy Alliance to augment energy diversification efforts. Finally, engineering architects in Indonesia signed a contract in January 2022 to build a floating thorium plant, which will produce 500 MW(e) when completed.

Managing Radioactive Waste: Nuclear Recycling in the US

Every year, the US produces 2,000 metric tons of spent fuel, equivalent to about half the volume of an Olympic-sized swimming pool. If you were to take all the spent fuel from 1950 to present day (90,000 metric tons), it would cover the length of a football field with rods stacked ~10 yards high. In theory, the plutonium and depleted uranium found in spent fuel can be recovered and used to make mixed-oxide fuel, which significantly increases the total energy derived from the original U-235 — in fact, if all existing spent fuel in the US were reprocessed today, there would be no need to harvest natural uranium for the next three years.

However, while countries such as France, Japan, Germany, Belgium, and Russia have established processes to refresh spent fuel and reduce their radiological footprint, the US shut down all reprocessing programs in 1977 and has not resumed any recycling activities since. At the time, this choice was ostensibly driven by national security concerns (i.e., anxiety that other countries might use commercial reprocessing of nuclear waste to augment their nuclear weapons programs), but the decision did not keep other countries from continuing to develop more efficient and advanced reprocessing technology, and today, the US lags far behind other large nations.

Instead, the current state of nuclear waste handling in the US involves storing all spent fuel on-site at commercial power plants across the country, where it serves no functional purpose and presents a heightened risk to the communities where those facilities are located. There was a coordinated effort to consolidate all domestic spent fuel in a facility under Yucca Mountain in the early 2000s, but this initiative lost funding in 2011. Fortunately, a recent grant from the DOE suggests that the government may be ready to explore a domestic nuclear recycling program once more. This $38 million initiative is spread across 11 different organizations working on technologies to advance nuclear fuel reprocessing technology, with the DOE’s Advanced Research Projects Agency-Energy (ARPA-E) coordinating the effort.

While nuclear power has been an established element of the global energy mix for many decades, growing urgency around clean (i.e., low carbon) energy is shaking things up. The advancements described here bode well for efforts to expand nuclear capacity, but they will also create an additional needs and challenges related to design, engineering, etc. As these innovations are adopted, new opportunities will arise for materials technology providers to solve key problems with the nuclear envelope, from radiation shielding to fuel handling to storage.

Find out how Newry can help your organization find high-value options for growth. Expand your pipeline before it runs dry.